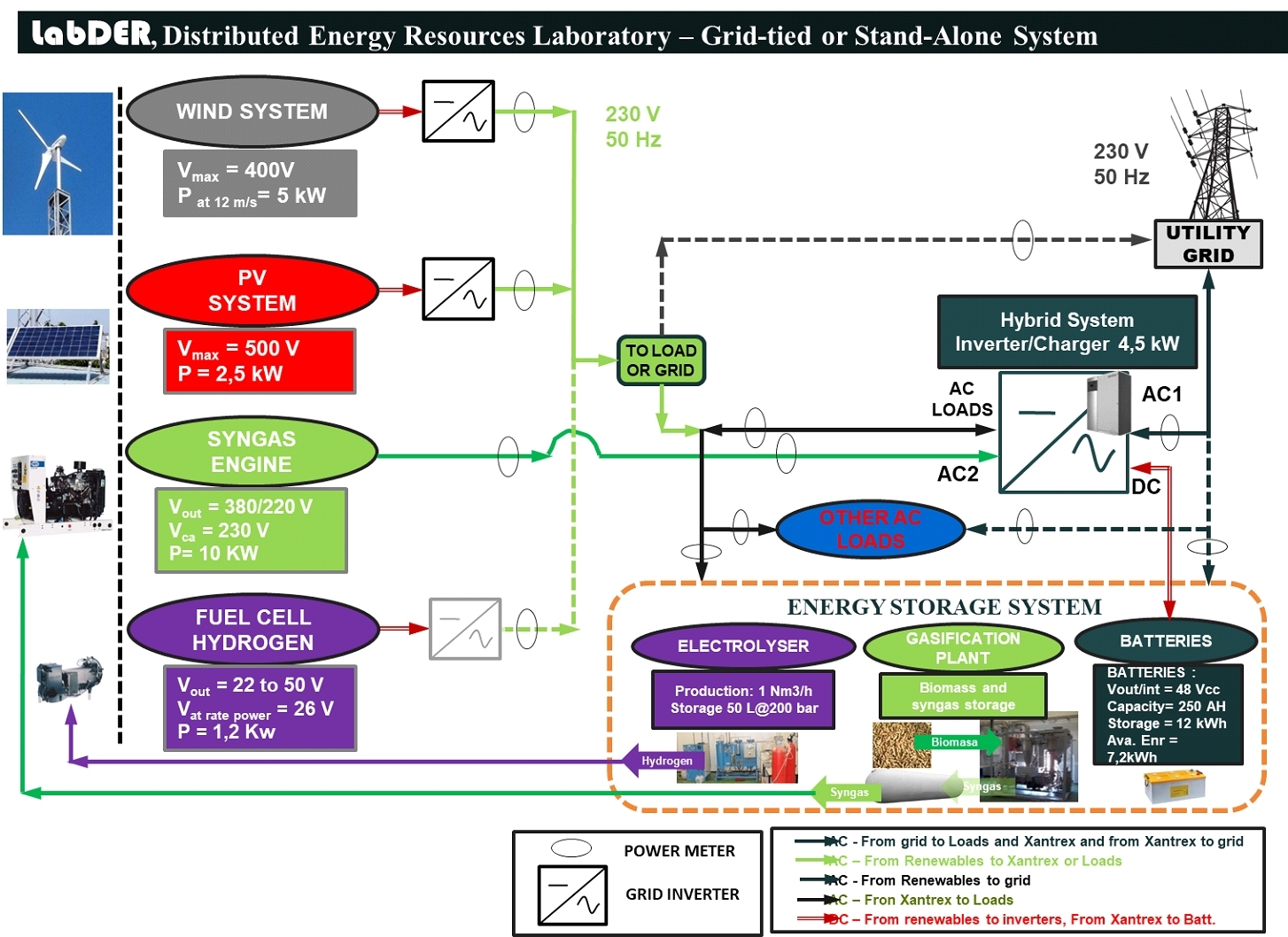

- Hybrid renewable system with data acquisition for the different energy flows and parameters of the generated electrical signal.

- Capability to operate either in island mode or grid‑connected mode, with the possibility of programming specific demand curves.

- Energy storage systems based on batteries and hydrogen + fuel cell.

The global energy landscape has been undergoing substantial changes in recent decades, showing a significant increase in demand that efforts to improve energy efficiency and savings have only been able to mitigate, but not fully prevent. This is not the only reason behind the serious energy challenge faced today: the high dependence on fossil fuels—around 85% worldwide—exacerbates the situation due to the scarcity and potential depletion of these resources, as well as their considerable environmental impact.

These two factors—the need for increased energy generation and the need to avoid massive dependence on fossil fuels—require integrating a significant contribution from renewable energies into the overall energy‑consumption framework. Together with the current scenario of decarbonization and the reduction of greenhouse‑gas emissions, this makes research on renewable‑energy production a subject of major technical and scientific interest.

The participation of renewables is necessary not only in grid‑connected systems, but also in non‑interconnected areas, where renewable energy can play a key role in boosting the development of regions that are often underdeveloped.

Conventional renewable sources—such as solar photovoltaic, biomass, and wind—have reached a level of technological maturity that makes it possible for them to replace fossil fuels in future energy scenarios.

The use of renewable energy both in islanded and grid‑connected operation also reduces energy costs, making production processes more competitive and helping decrease energy poverty.

The major challenge for achieving such penetration lies in the reliability of renewable sources—particularly in isolated systems, but also in grid‑connected ones when the share of renewable generation reaches substantial levels, as required for a sustainable energy system. A possible solution to this reliability issue is the combination of several different renewable sources, thereby forming a hybrid system, and/or the incorporation of an energy storage system.

Hybrid Renewable Energy Systems (HRES) have sufficient potential to address this reliability problem, thanks to technological advances in renewable‑energy generation and in their associated power electronics and control systems.

By combining two or more renewable‑energy systems, it is possible to overcome the reliability limitations of each individual source and achieve improvements in overall system efficiency compared to their separate performance. In summary, HRES systems can overcome the typical limitations of renewable sources in terms of fuel‑use flexibility, energy‑supply reliability, and cost.

Because of this potential, numerous studies have been conducted to optimize their design and simulate their behavior. However, before developing large‑scale hybrid systems, it is essential to experimentally verify their capabilities at the minimum significant power level.

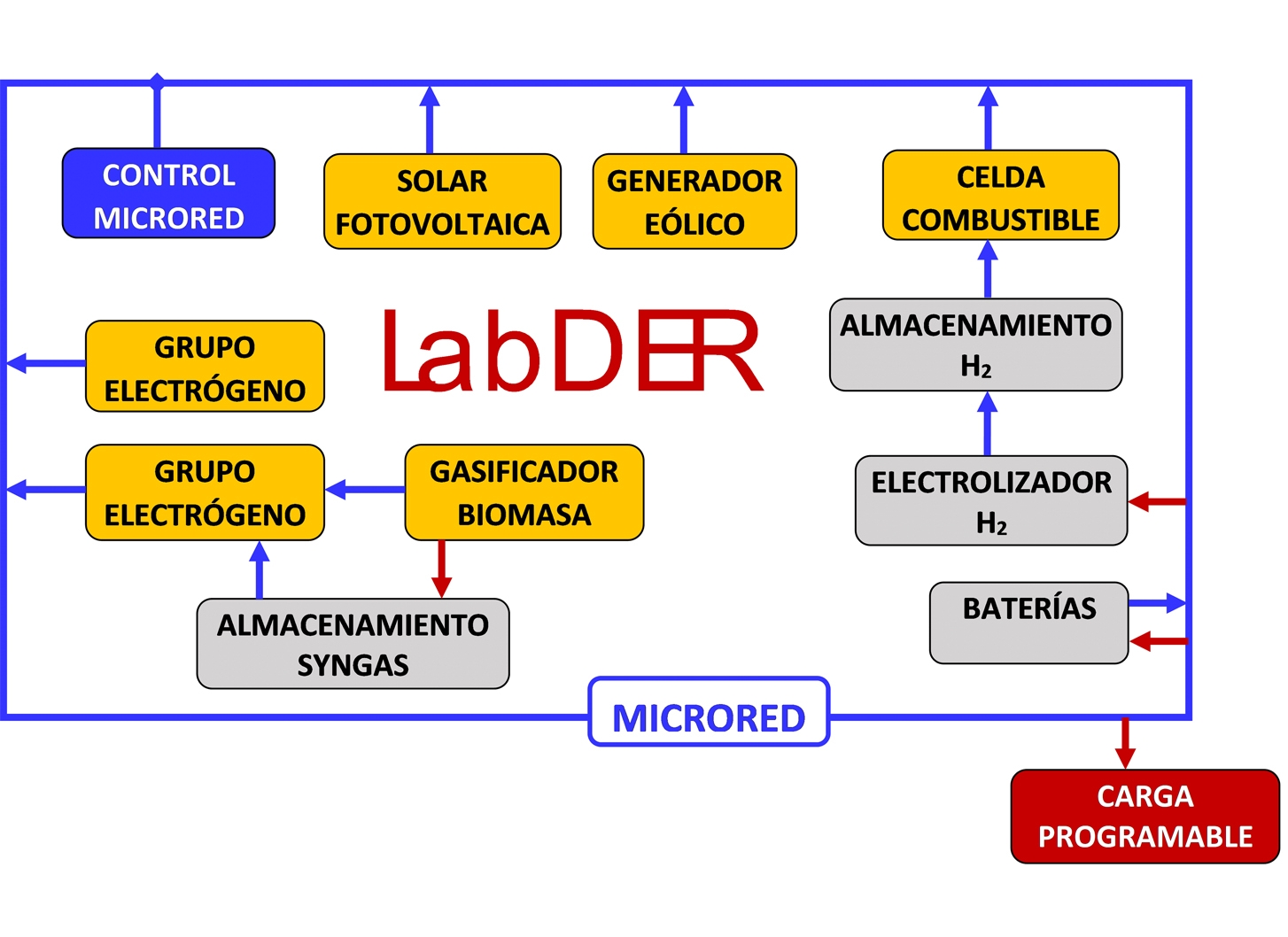

With this objective, the Distributed Energy Resources Laboratory (LabDER) of the Institute for Energy Engineering at the Universitat Politècnica de València was established. Its purpose is to study hybrid renewable‑energy systems in the kilowatt range and to design and participate in higher‑power field experiments.

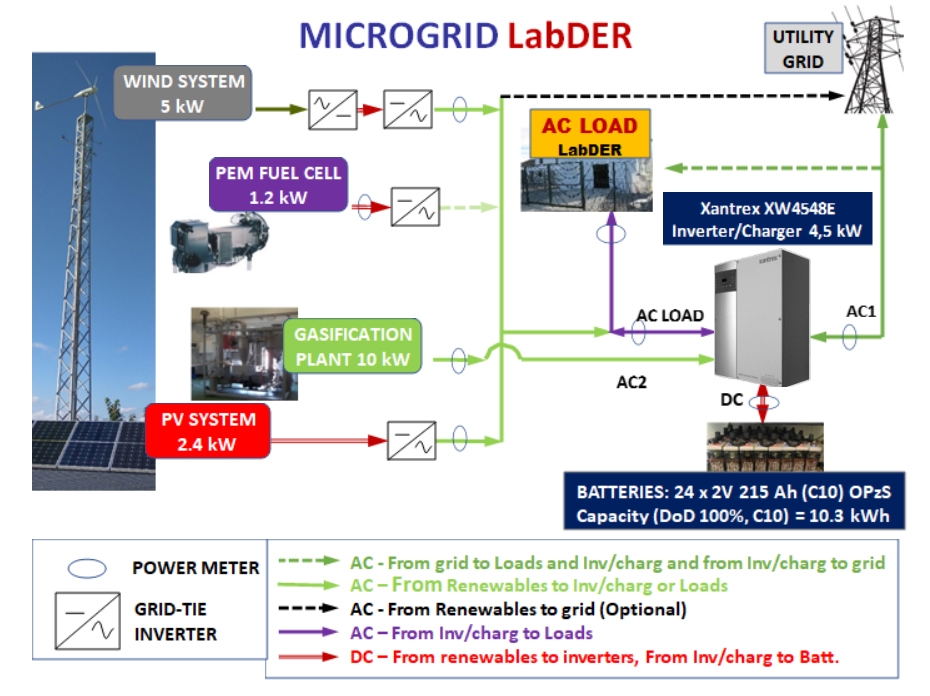

This laboratory incorporates several renewable sources—photovoltaic, wind, biomass, and fuel cell—all interconnected through a controlled microgrid supplying a load with a predefined demand curve. This allows verification of the ability of different HRES configurations to reliably meet a given demand. Additionally, the laboratory includes battery‑based and hydrogen‑based storage systems, enabling the testing of virtually all possible HRES configurations.

LabDER supports R&D&I activities in numerous areas, including renewable energy, energy efficiency, distributed energy resources, and hydrogen as an energy vector.

LabDER is located on the Vera Campus of the Universitat Politècnica de València.

LABDER enables R&D&I activities in a wide range of areas, including Renewable Energies, Energy Efficiency, Distributed Energy Resources, and Hydrogen as an energy vector.

The objectives of LabDER are:

- To develop hybrid renewable systems in the kilowatt range, optimizing their reliability through innovative interconnection and storage techniques.

- To develop control strategies that ensure the reliability of the electricity supply through the combination of various renewable‑energy sources.

- To apply these hybrid systems in field experiments conducted in non‑interconnected areas.

- To study the potential of hydrogen as an energy vector and as an energy‑storage solution in renewable‑energy systems.

- To improve the efficiency of renewable‑energy systems, both in standalone operation and when configured as hybrid systems.

- To develop and investigate high‑reliability, high‑efficiency electrical distribution networks, powered by multiple interconnected renewable sources.

- To validate the modeling of hybrid renewable systems through real laboratory experiments. LabDER analyzes modeling systems using genetic‑algorithm approaches, among others. The tools used include Matlab‑Simulink, Homer, and TRNSYS.

- To determine the optimal location of generation plants through the use of GIS systems (QGIS and ArcGIS).

- To perform analyses for integrating electric vehicles as active components of the power network, using their battery‑storage capability.

- Biomass

- Solar

- Wind Energy

- Hydrogen

- Microgrid

- Diagnostics and Control

A) BIOMASS

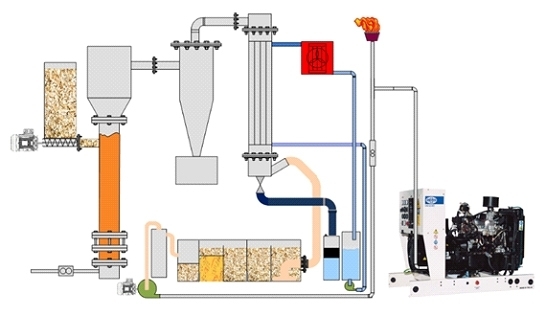

LabDER is a pioneer in biomass gasification systems in the Valencian Community and in Spain. The facility includes two biomass gasification plants, both rated at 10 kWe. One uses a downdraft fixed-bed technology, while the other operates with a bubbling fluidized-bed technology.

The produced gas is used to generate electrical power through an internal combustion engine. These plants are used to investigate energy production through biomass gasification, mainly using woody biomass, although other feedstocks can also be tested.

The plants are designed, built, and commissioned by the research group itself.

Planta de gasificación de lecho fluido burbujeante

Watch video of the operation of LabDER’s bubbling fluidized‑bed gasification plant.

In addition, a laboratory is available for biomass characterization through the determination of parameters related to energy production: ash content, calorific value, volatile matter, solid fraction, density, and others.

Alongside the studies on hybrid systems that incorporate biomass technologies, LabDER’s infrastructure in this field enables the continuation of R&D lines initiated at the IIE and specifically focused on biomass. These include the comprehensive utilization of resources available in the Valencian Community, methodologies to ensure the technical, economic, and logistical viability of biomass use, the optimization of gasification techniques, and the development of the biorefinery concept.

B) SOLAR

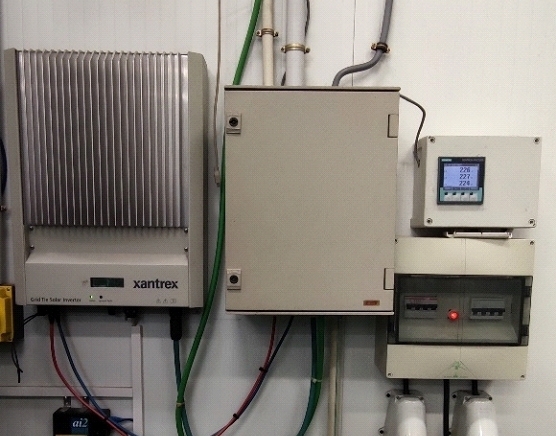

LabDER has a 2.5 kWp photovoltaic solar plant composed of crystalline‑silicon panels (both mono‑ and polycrystalline), equipped with a calibrated cell for irradiance measurement. Power generation can be monitored through the energy management system, enabling the study of hybrid systems that incorporate photovoltaic technology.

Tests with panels based on different technologies are planned in order to evaluate the impact that their use may have on the hybrid system.

Bp solar – BP 7190S – 2385W

Grid-tie solar inverter Xantrex GT 2.8

C) WIND ENERGY

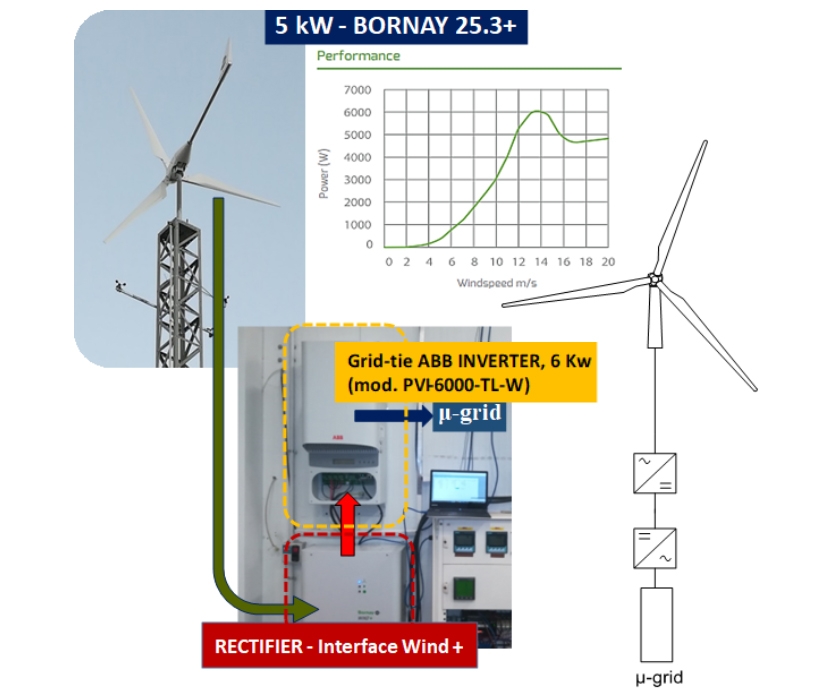

LabDER has a 5 kW peak three‑phase permanent‑magnet synchronous wind turbine from BORNAY. It generates alternating current, which is converted into direct current through an active rectifier; this DC power is then sent to a grid‑tie inverter that converts it into 230 V, 50 Hz alternating current and synchronizes it with the grid.

The wind turbine is installed at a height of approximately 24 meters in order to achieve higher wind speeds. The lattice tower is reinforced and oversized to allow the interchange of different wind turbines (including higher‑power models) for testing purposes, with the objective of optimizing electrical production.

As with the photovoltaic solar system, the wind system can inject energy into the grid, supply loads, or store the generated energy either in batteries or as hydrogen.

D) HYDROGEN AND FUEL CELL

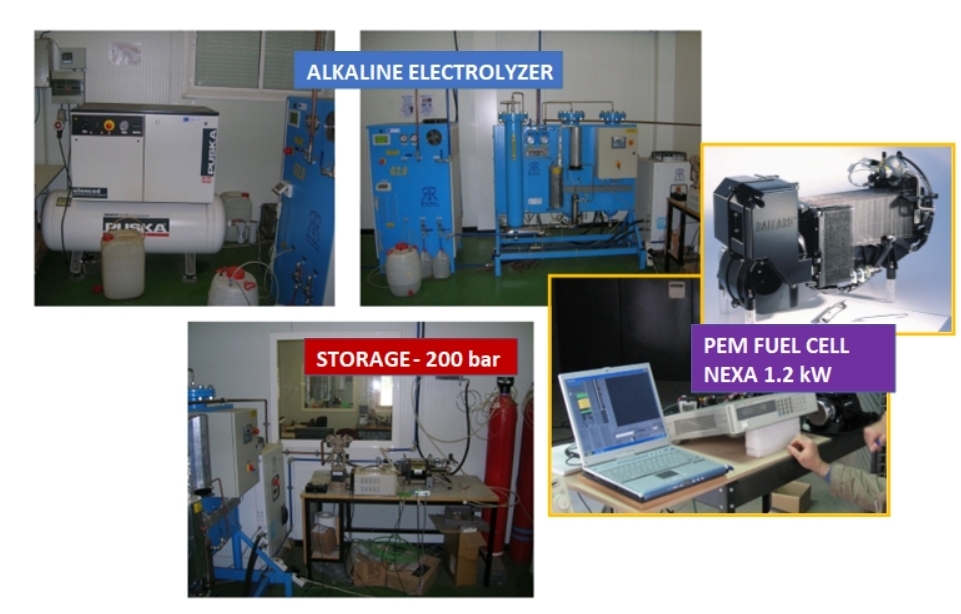

The hydrogen plant at LabDER serves as an energy storage system capable of absorbing excess production from renewable sources and supplying energy when the other renewables connected to the microgrid are unable to meet the required demand.

The hydrogen plant consists of a water electrolysis system, a compressor, a storage cylinder, and a PEM fuel cell.

The system includes an electrolyzer with a maximum power of 7 kW, capable of generating 1 Nm³ of hydrogen at 4 bar and with a purity of 99.9%. This impurity level is not suitable for fuel cells based on PEM (Proton Exchange Membrane) technology, so the hydrogen must be purified until reaching a purity of 99.9999%. For this purpose, the DPSH6 hydrogen purifier is used.

The G2 electrolyzer is a commercial unit designed to supply hydrogen according to downstream consumption needs. Since its role in our storage system is to absorb surplus energy from the other renewable sources, this is achieved by regulating the hydrogen flow demanded by the line.

The selected storage system consists of a 50‑liter geometric cylinder rated for a pressure of 200 bar. This storage method combines the intrinsic safety of compressed‑gas cylinders with minimal space requirements. However, the energy expenditure associated with increasing the working pressure must be considered. Pressure elevation is performed by the booster located between the valve and the cylinder. In addition, the piston movement speed determines the hydrogen flow extracted from the line, making this element the key actuator for controlling the energy consumed by the electrolyzer. The booster allows the hydrogen pressure to be increased up to the cylinder’s maximum rating of 200 bar.

Both the hydrogen purifier, the solenoid valve, and the booster require compressed air at 6 bar for their actuation.

The hydrogen stored by the electrolyzer is used in a 1.2 kW PEM (Proton Exchange Membrane) fuel cell from Ballard. A DC/AC converter enables the integration of the energy produced by the fuel cell into the microgrid (although it is not currently connected).

F) MICROGRID

All renewable sources and storage systems are connected to an electrical microgrid, either directly—as in the case of the gasification plant—or through grid‑tie inverters, as is the case for the photovoltaic panels, the wind turbine, and the fuel cell.

The microgrid is connected to a set of loads whose electrical demand can be programmed in order to generate different consumption curves and to study the behavior and stability of the hybrid generation system under various energy‑demand scenarios.

All parts of the microgrid pass through a main protection and switching panel, from which any component can be connected or disconnected. This panel also provides basic protection against overloads and short circuits. It is equipped with measuring devices on each circuit, allowing the operation of every component to be monitored.

To operate in island mode and charge the batteries, the system uses the Schneider Electric Xantrex XW4548‑230‑50, which regulates the different power flows among the connected elements and can be expanded in the future with proprietary equipment to add new functionalities.

The current design allows the study of hybrid system behavior under different production and consumption scenarios, the analysis of the dynamic performance of the system’s elements, and the simulation of remote placement of any component by inserting appropriate impedances to model the electrical connection lines.

To vary the consumption conditions of the electrical network into which the renewable production systems will inject energy, the use of a variable three‑phase load was required. Given the high cost of commercial electronic loads, a programmable load with discrete power steps was built, sufficient to simulate the behavior of a group of users. The system consists of 10 rheostats that allow reaching a stepped load of up to 9 kW.

A microgrid includes the same elements as a conventional grid—generators, loads, and control systems—while also allowing the integration of energy storage devices. However, although conceptually these components perform the same functions as in a large‑scale grid, their operation, and especially their control and protection systems, must be adapted to operate appropriately according to the microgrid’s operational philosophy.

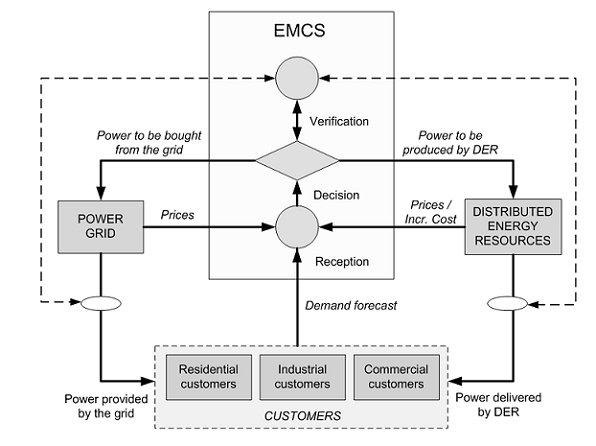

At LabDER, grid management is approached under two control premises: improving the energy efficiency of the systems involved and providing the necessary tools to facilitate demand response within the electrical system.

As a result of the research, the goal is to develop an Energy Management and Control System (EMCS) capable of managing different types of microgrids, whether electrically isolated or grid‑connected.

The connection of the different microgrid components is carried out through a switching panel that allows the remote connection and disconnection of the various systems.

For microgrid management, a control system is available which, based on different operating criteria, defines the optimal operating state, sets the operating parameters of the different components, and performs the necessary actions to ensure proper system operation. The control system consists of a central server that enables interaction with the system operator, as well as programmable logic controllers (PLCs) in the various generation systems. This architecture enables distributed control.

A data acquisition and storage system is also available, allowing the analysis of consumption in each of the systems that make up the microgrid. The State Monitoring and Fault Diagnosis System makes it possible to determine the condition of the equipment and systems involved in LabDER’s microgrid. This, in turn, facilitates maintenance planning and speeds up repair actions, improving the reliability of the network. For both state monitoring and fault diagnosis, the system captures information from the equipment integrated into the network and continuously compares it with analytical and heuristic models, enabling the detection of deviations in the behavior of components, equipment, and systems.

- TGA‑701 thermogravimetric analyzer, with the capacity to analyze 19 samples in parallel.

- CAL2k calorimeter for the analysis of the lower heating value (LHV) of solid fuels.

- Proximate analysis equipment (ceramic crucibles, 1100°C muffle furnace, precision balance, and sample homogenization mill).

- Bulk density analysis of solid biofuels.

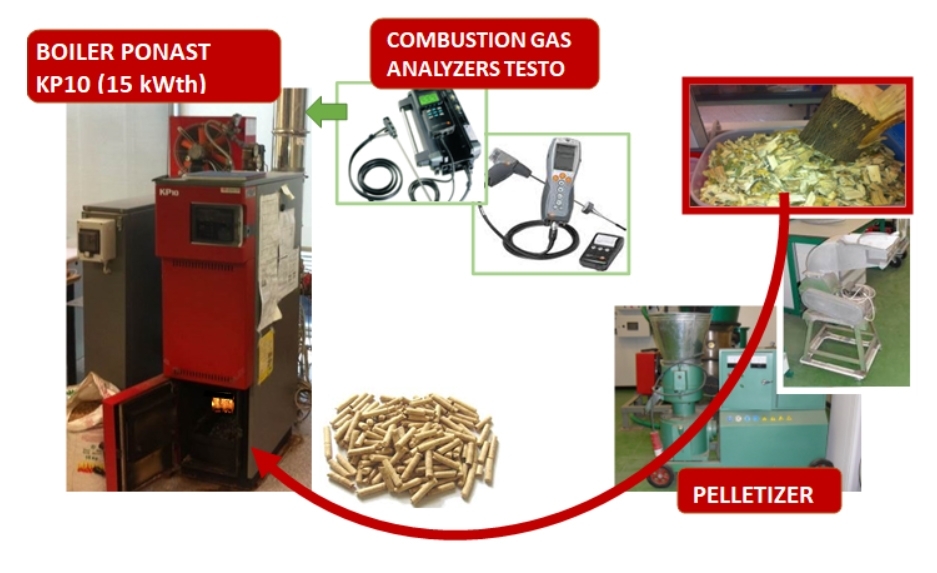

- 14 kWt pellet/chip combustion boiler with screw‑feeder system and Testo 335 and Testo 350 flue‑gas analyzers.

- Systems for chipping, crushing, and pelletizing solid biofuels.

In the solid biofuel characterization laboratory (laBIO), the necessary equipment is available for evaluating the energy‑related properties of solid biofuels, which are subsequently used in the combustion and gasification facilities.

- TGA‑701 thermogravimetric analyzer, with capacity for 19 samples in parallel.

- CAL2k calorimeter for determining the higher heating value (HHV) of solid fuels.

- Equipment for proximate analysis (ceramic crucibles, 1100°C muffle furnace, precision balance, chipper, and sample homogenization mill).

- Equipment for bulk‑density analysis of solid biofuels.

- Systems for chipping, crushing, and pelletizing solid biofuels.

In the laboratory, there is also a 15 kW biomass boiler (PONAST KP10) with screw‑feeder supply, used to investigate biomass combustion optimization techniques based on the fuel’s characteristics. Combustion quality is analyzed using a TESTO 335 and a TESTO 350XL flue‑gas analyzer, measuring the volumetric concentration of CO, CO₂, O₂, NOx, and SOx. In addition, combustion losses and efficiency are calculated.

The laboratory also includes equipment for preparing biomass for use in both boilers and gasifiers. For this purpose, it is equipped with a chipper/shredder, a hammer mill, and a pelletizer.